Manual Needle Destroyer – 0.8Ltr.

$0.00

Shipped From Abroad

This 0.8-litre manual needle destroyer provides a safe, efficient solution for disposing of used medical needles. Its durable design supports hygienic waste management in clinics, labs, and home care, helping prevent needle-stick injuries without requiring electricity or complicated maintenance.

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

Description

Features:

-

0.8 Litre Capacity: Suitable for small to medium sharp volumes.

-

Manual Operation: No power or battery required.

-

Durable Build: Constructed from medical-grade plastic (ABS or polycarbonate).

-

Stainless Steel Blade: Corrosion-resistant for long-term use.

-

Safety Design: Enclosed cutting mechanism reduces the risk of injury.

-

Compact & Lightweight: Easy to handle and transport.

-

Eco-Friendly: Reduces sharps volume and enables safe disposal.

Usecase

- Destroys Syringe Hub & Needle in Single Action

- Stops Reuse of Needles and Syringes

- Saves Healthcare Professionals from Needle Stick Injuries.

- No Electricity Required.

- No Burning, No Fumes

- No Noise, No Smell

Specifications:

| Specification | Details |

|---|---|

| Model | Manual Needle Destroyer – 0.8Ltr. |

| Body Material | ABS / Polycarbonate |

| Capacity | 0.8 Litres |

| Operation | Manual (hand-operated) |

| Blade Type | Stainless Steel (non-corrosive) |

| Dimensions | 13 cm (H) × 11 cm (D) |

| Weight | ~250 grams |

| Color | Typically white/transparent body with colored lid |

| Disposal Compliance | Follows biomedical waste disposal norms |

Quick Comparison

| Manual Needle Destroyer – 0.8Ltr. remove | Manual Needle Destroyer – 0.8Ltr. Polycarbonate Body remove | Manual Needle Destroyer – 5 Ltr. remove | ABS Body Manual Needle & Syringe Cutter remove | Sharps Containers – PBS Series 2 LT remove | STERIPLUS 80 remove | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Manual Needle Destroyer – 0.8Ltr. remove | Manual Needle Destroyer – 0.8Ltr. Polycarbonate Body remove | Manual Needle Destroyer – 5 Ltr. remove | ABS Body Manual Needle & Syringe Cutter remove | Sharps Containers – PBS Series 2 LT remove | STERIPLUS 80 remove | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Image |  |  |  |  |  |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SKU | SF103356013097-3 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rating | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Price |

|

|

|

|

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stock | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Availability | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Add to cart | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Description | Shipped From Abroad

This 0.8-litre manual needle destroyer provides a safe, efficient solution for disposing of used medical needles. Its durable design supports hygienic waste management in clinics, labs, and home care, helping prevent needle-stick injuries without requiring electricity or complicated maintenance.

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| Shipped From Abroad

This 0.8-litre manual needle destroyer features a tough polycarbonate body for long-lasting use. Designed for safe and hygienic disposal of used needles, it’s ideal for clinics, labs, and mobile healthcare settings, effectively reducing contamination risks and supporting safe biomedical waste practices. Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| Shipped From Abroad

This 5-litre manual needle destroyer is built for high-capacity medical facilities requiring safe and hygienic disposal of large volumes of used needles. Its heavy-duty construction and manual operation ensure reliable performance without electricity, making it ideal for hospitals, camps, and emergency services.

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| Shipped From Abroad

This ABS body manual needle and syringe cutter offers a reliable, safe solution for disposing of used medical sharps. Designed for hospitals, clinics, and mobile health units, it’s durable, user-friendly, and promotes hygienic waste management while minimizing the risk of needle-stick injuries.

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| Shipped From Abroad

The PBS Series 2 Ltr Sharps Container offers a safe and efficient solution for disposing of syringes, needles, and lancets. With a puncture-proof body, secure locking lid, and biohazard labeling, it’s designed for medium-volume use in clinics, labs, and mobile units. Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

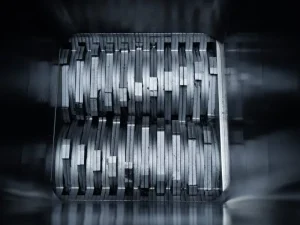

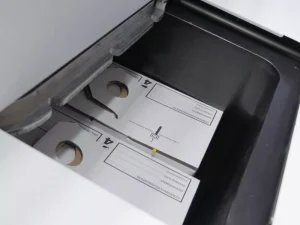

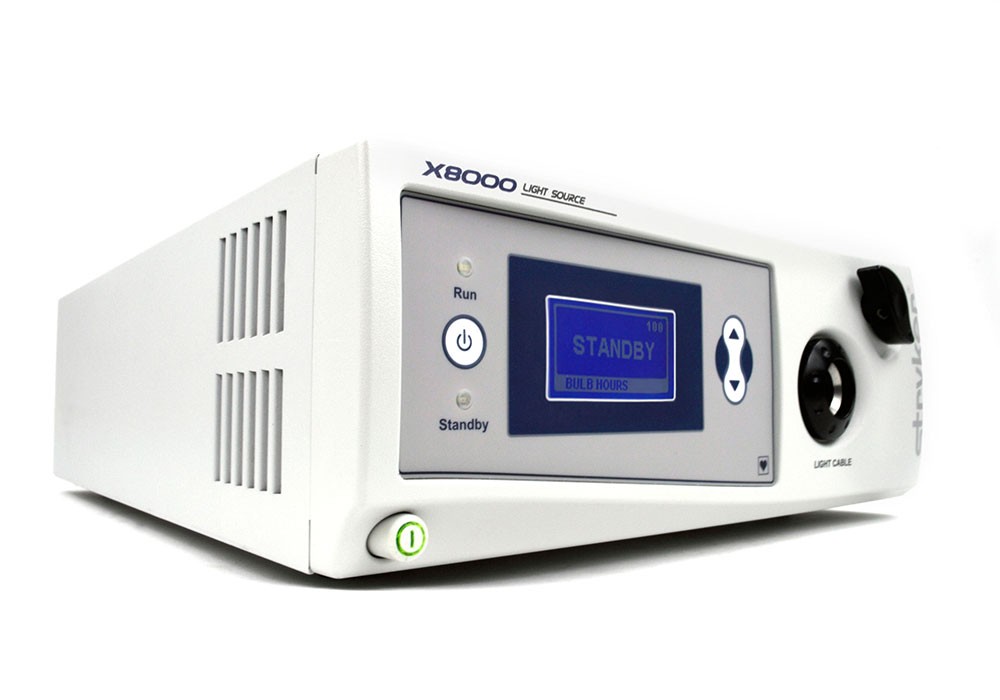

| Shipped From Abroad

INTEGRATED INFECTIOUS WASTE PRE-SHREDDING AND STEAM STERILIZATION SYSTEM

Tesalys STERIPLUS ™ systems are the ideal solution to safely inactivate your infectious waste on site. Their integrated TESASHRED ™ shredding system not only allows a consequent reduction in the volume and weight of waste, but also guarantees their treatment at heart.

Click here to download CatalogueDelivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Content | Features:

Usecase

Specifications:

| Features:

Specifications:

| Features:

Specifications:

| Features

Typical Use Case:

Benefits:

| Features:

Specifications:

| STERIPLUS 80On-site infectious risk waste treatment solutionhttps://youtu.be/ahPvNNrzIMk?si=8dLL5Pn1YWY_sUM7

FeaturesFully automated

The STERIPLUS™ 80 is an easy-to-use, on-site processing solution.

Large capacity

The loading chamber has a capacity of 80 litres, i.e. 1 TESABOX 80 or 2 TESABOX 40 or 4 TESABOX 20.

Fully integrated system

The STERIPLUS™ 80 is a fully automated solution for pre-grinding and steam sterilization of infectious wastes.

Technical Data

Utilities

Accessories | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Weight | N/A | N/A | N/A | N/A | N/A | N/A | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dimensions | N/A | N/A | N/A | N/A | N/A | N/A | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Additional information |

Reviews

There are no reviews yet.