DISSUB ANALYSER

$0.00

Shipped From Abroad

Key Features

- Proven hyperbaric sensing capability

- You have the ability to change sensors and maintain the unit in the dockyard, reducing costs and downtime

- Backlit display for low/no light situations

- Portable and lightweight making it easy to use around the submarine

- Externally accessible batteries making for more convenient and safer changing

- MODBUS RTU over RS485 digital communications, allowing for easy incorporation into your existing platform management system, including JANUS enabled underwater communication networks

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

Description

Description

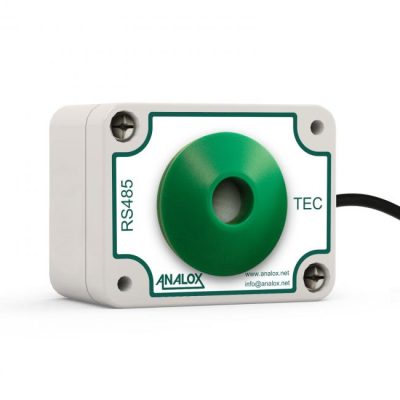

The Sub Mk3P Continuous Gas Monitor from Analox is designed specifically to monitor life support gasses aboard a submarine in the event of a distressed submarine (DISSUB) situation.

Portable and lightweight, the Sub Mk3P monitor provides crucial information to the senior survivor about the state of the atmosphere inside the submarine during a time of crisis. This information helps that officer make one of the most challenging decisions any submariner ever has to make – attempt to escape the submarine or wait for rescue teams.

Technical Specification

Temperature & Humidity Sensor

Main Unit

| Battery power | 4 x ‘D’ alkaline cells (Hyperbaric) |

| External power | 24V dc (9-36V dc), <0.5A |

| Backup batteries | 2 x LR43 alkaline manganese cells |

| Displays | 6 x 4 character LCD, with symbols and LED backlights |

| Operating temperature | -5 to 50°C |

| Storage temperature | -5 to 50°C |

| Operating pressure | 0.7 to 10barA |

| Operating humidity | 0 to 100%RH (Non-condensing) |

| Standards/ compliance | NATO STANAG 1476:2014 ANEP/MNEP 85 & 86 (2014) DEF STAN 59-411:2014 (EMC) IACs E10:2014 (MarED) type tested IP65 CE marked (RoHS)” |

| Dimensions (W, H, D) | 240mm x 198mm x 127mm |

| Weight | 2kg with batteries installed |

O2 Sensor

| Range | 0 to 2000mbar pO2 |

| Accuracy | ±10mbar (0 to 300mbar pO2) ±50mbar (300 to 2000mbar pO2) |

| Response time (t90) | 20s |

| Detection mode | Electro-chemical |

| Shelf life (in sealed packaging) | 6 months |

| Expected life (in air) | 12 months |

CO2 Sensor

| Range | 0 to 100mbar pCO2 |

| Accuracy | ±10mbar |

| Response time (t90) | 60s |

| Detection mode | Infrared |

| Expected life (in air) | 5 years |

Pressure Sensor

| Range | 0.7 to 10barA (-3 to 90MSW or -10 to 300FSW) |

| Accuracy (including annual drift) | -0.07bar +0.04bar |

| Response time (t90) | <1s |

| Detection mode | Piezoresistive |

| Expected life (in air) | >12 months (Replaced as a part of the O2sensor) |

Click here to download Data Sheet

Click here to download Technical Manual

Quick Comparison

| DISSUB ANALYSER remove | LIGHTWEIGHT PERSONAL CO2 ALARM remove | Pipette Holder remove | COMPRESSED BREATHING AIR MONITOR remove | Bunsen Burner remove | PORTABLE OXYGEN MONITOR remove | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | DISSUB ANALYSER remove | LIGHTWEIGHT PERSONAL CO2 ALARM remove | Pipette Holder remove | COMPRESSED BREATHING AIR MONITOR remove | Bunsen Burner remove | PORTABLE OXYGEN MONITOR remove | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Image |  |  |  |  |  |  | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SKU | SF1033560130141-17 | SF1033560130141-10 | SF1033560084-148 | SF1033560130141-3 | SF1033560084-155 | SF1033560130141-18 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rating | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Price |

|

|

|

| $4.25 |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Availability | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Add to cart | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Description | Shipped From Abroad

Key Features

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| Shipped From Abroad

Key Features

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| In stock

The linear and round stands have been designed to fit perfectly of TOPTION Pipette range, TopPette,MicroPette and MicroPette Plus Autoclavable Pipettes. The stands are convenient to hold up 6 pipettes both of single and multi-channel.

| Shipped From Abroad

Key Features

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| In stock

| Shipped From Abroad

Key Features

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Content | DescriptionThe Sub Mk3P Continuous Gas Monitor from Analox is designed specifically to monitor life support gasses aboard a submarine in the event of a distressed submarine (DISSUB) situation. Portable and lightweight, the Sub Mk3P monitor provides crucial information to the senior survivor about the state of the atmosphere inside the submarine during a time of crisis. This information helps that officer make one of the most challenging decisions any submariner ever has to make – attempt to escape the submarine or wait for rescue teams.Technical SpecificationTemperature & Humidity Sensor Main Unit

Click here to download Data SheetClick here to download Technical Manual | CO2 MONITORING WITH THE CO2 BUDDYCarbon Dioxide Sensor The CO2BUDDY uses state-of-the-art Non-Dispersive Infrared (NDIR) technology to detect CO2. The NDIR system monitors the air in the surrounding environment for the specific CO2 elements. No additional “control” or “calibration” gasses are needed. The simple-to-operate unit protects users and those nearby by alerting them to CO2 leaks or buildup with multiple alarms – a high visibility LED display, a loud and powerful audible alert and a powerful vibration motor. The vibration setting is ideal for workers in noisy environments where the audible alarms could be drowned out by background noise. Users can customize which alarm setting they prefer. The CO2BUDDY has multiple set-points to comply with the most common safety regulations and jurisdictional requirements, which can be different by country, region, state and municipality. The unit comes with pre-configured alarm set points that meet safety standards across the globe including Europe’s EH40 legislation, OSHA and NIOSH TWA requirements in the United States.Technical SpecificationCO2 BuddyCharacteristicsCalibrate on site Unlike most portable CO2 monitors which require you to send the device back to the manufacturer for calibration, the CO2BUDDY allows you to calibrate on site, all you need is fresh air! Saving you time and money, the CO2BUDDY is perfect for those who like to get the job done.Built for user convenience Very simple to operate, the user can select the pre-configured alarm set points which all feature a TWA (Time Weighted Average) alarm, continuously monitoring the environment over an 8-hour period. The environmentally-friendly CO2BUDDY features a rechargeable battery that can easily last a minimum of 48 hours on a single charge. The unit is designed to be charged overnight or during off-hours, virtually eliminating the need for service returns or battery replacements.Reliable This advanced monitor is also extremely durable, offering long-lasting sensor life and reliable personal monitoring for virtually anyone who may come into contact with CO2 during the course of their day. The CO2BUDDY has been providing an added level of safety and security worldwide since its introduction in 2019. This impressive REVIEW OF CO2BUDDY BY SeetheAir.org provides a fresh perspective of the product’s benefits and specific applications.CO2 exposure While brief exposure to CO2 is common throughout the workday, it’s the potential build-up of the gas from different locations that can often put employees at risk. The CO2BUDDY monitors the average CO2 level over an 8 hour period and will alarm when the overall exposure becomes harmful. Lightweight, portable and highly effective, the CO2BUDDY is one of the smallest and lightest personal CO2 monitors available today. Designed with user comfort and convenience in mind, the unit can be clipped to a shirt pocket, belt or lanyard with little interference with the monitoring process.Tried, tested and Trusted The CO2BUDDY is currently in use worldwide in such diverse industries as food and beverage, hospitality, research laboratories, medical facilities with cryogenic process monitoring, food processing and storage facilities and stadiums. Gas delivery drivers who service many of these industries on a daily basis are key target users of the CO2BUDDY. From initial power up, you must allow a two-hour charge and perform a quick fresh air calibration. Your CO2BUDDY is then ready to protect you!Download Quick Start GuideClick here to download Data Sheet | The linear and round stands have been designed to fit perfectly of TOPTION Pipette range, TopPette,MicroPette and MicroPette Plus Autoclavable Pipettes. The stands are convenient to hold up 6 pipettes both of single and multi-channel.

Features:

| A Reliable ToolThe ACG+ offers continuous monitoring of up to five different gas variables (oxygen, carbon monoxide, carbon dioxide, volatile organic compounds and water vapor) and simultaneously displays results for testing and calibration purposes. This eliminates potential delays and downtimes while test results are sent out for analysis. The ACG+ has also made cumbersome colorimetric tubes obsolete by drastically reducing the potential for human error in gas analysis. The continuous monitoring also has virtually eliminated the need for time-consuming spot checks. The ACG+ simultaneously scans for O2, CO2, CO, VOCs and water vapor, making it one of the most versatile tools any vessel can utilize. The automatic data log provides additional peace of mind for decision makers.A Cost Effective SolutionYou can’t put a price on safety, reliability and peace of mind. The Analox development team created the ACG+ to combine multiple tasks simultaneously, reducing the need for multiple analyzer units, costly test tubes, and often, extended times in port for repairs. The ACG+ is available in either a fixed location model or convenient portable units. This adaptability provides designers, procurement officers and equipment specialists some options in closed quarter situations.A Tool, Easy To Install And MaintainWhile each ACG+ unit can monitor up to five gasses simultaneously, each analytical system operating in the ACG+ is independent of the others. This means sensors can be replaced individually without needlessly causing downtime.An Easy ChoiceThe Analox ACG+ has been proven effective in military situations around the world. The unit’s continuous and specific monitoring capabilities make it an easy choice for key decision-makers. Technical SpecificationsACG+

Click here to download Data SheetClick here to download Quick Start GuideClick here to download User Manual |

| DescriptionThe O2 Portable is an oxygen monitor designed to provide sample readings from cylinders containing different levels of O2. The O2 Portable is supplied with a sampling adaptor to be easily fitted to cylinders. O2 MONITORING WITH THE O2 PORTABLEEnsuring the oxygen content of a cylinder is correct is vital to ensure the safety of the end user. The O2 Portable provides a fast and accurate reading of O2 levels in that cylinder, easy to use as an instant spot check, the handheld unit is quick and simple to operate, with a robust design.

The O2 Portable has a large digital display and operates from an internal temperature compensated 3 year life (expected) electrochemical oxygen sensor. Power is provided by a 9V, 4000-hour life battery giving up to 3 years of operation before replacement is necessary.

Click to download Data SheetClick here to download User ManualClick here to download Quick Start Guide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Weight | N/A | N/A | N/A | N/A | N/A | N/A | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dimensions | N/A | N/A | N/A | N/A | N/A | N/A | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Additional information |

Reviews

There are no reviews yet.