Medical Waste Incinerator 100kg

$0.00

Shipped From Abroad

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

Description

Characteristics

The main characteristics and scope of application of incinerator

LDF series medical waste incinerator is a medical waste incineration equipment with independent intellectual property rights developed by Shandong Lvdu Environmental Equipment Co., LTD., which introduced the world’s advanced medical incinerator technology and organized technical experts to tackle key problems. The equipment has the characteristics of full closure, small size, high incineration efficiency, reasonable process, leading technology, and high degree of harmfulness. It is an ideal garbage disposal equipment for all kinds of hospitals, hotels, stations, large commercial institutions, enterprises, and public institutions. Main features:

1. Gasification incineration technology is applied to the incineration of syringes, drip containers and other medical equipment as well as all kinds of paper waste, bandages, absorbent cotton, all kinds of medical sewage and all kinds of waste discharged by hospitals and medical institutions.

2. Using gasification incineration method, the waste generated every day can be incinerated once.

3. The use of gasification incineration, mixed incineration, burnout treatment and other technologies, so that the exhaust smoke, soot content is lower than the national emission standards.

4. Fully enclosed operation, suitable for the treatment of infectious medical waste, to avoid secondary pollution.

5. Small size, small footprint.

6. The series of incinerators are divided into fuel oil and gas, and users can use different types according to their needs.

Technical characteristics of incinerators

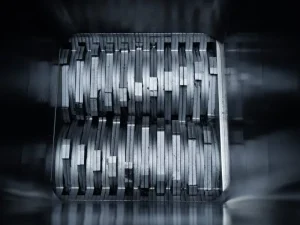

LDF series medical waste incinerator adopts the most advanced incineration method of primary pyrolysis gasification + wind cocombustion + secondary incineration + burnout treatment. The design of the primary combustion chamber of the incinerator adopts the gasification incineration technology to make the temperature in the incinerator shift from 200ºC to 400ºC, and the waste will not produce frit, slag, sintering and other problems in the incineration process. Compared with direct combustion furnace and other furnaces, the dust production of gasification incinerator is very small, and secondary combustion burners and circumferential air supply devices are installed in the secondary mixed incineration chamber. At high temperatures, the combustible gas in the flue gas can be fully burned, and the gas produced by the gasifier can be fully mixed with the air to burn efficiently, preventing the carbon in the gas flame from escaping and the occurrence of late burning. When the flue gas enters the high temperature burnout chamber, due to the use of tangential entry and tangential entry of combustion-supporting air, the flue gas can be fully burned again in the burnout chamber, and the use of rotating airflow for flue gas dust removal. The residence time of the incinerator flue gas in the furnace is greater than 2 seconds, so that the combustible gas in the flue gas and the combustible matter in the fly ash are completely incinerated. The upper part of the incinerator is equipped with dry tail gas purification equipment to adsorb hydrogen chloride and sulfur oxides produced in the incineration, and the odor and other components in the flue gas are decomposed at high temperature. The flue gas purification system is equipped with calcium hydroxide filter brick for neutralizing reaction with acid gas to achieve the purpose of adsorption of acid gas and purification of tail gas. The harmful components in the flue gas are reduced to the national “Hazardous Waste incineration Pollution Control Standard (GB18484-2001)” and other standards below the specified value.

The operation control of the incinerator adopts automatic program control, which reduces the labor degree of the workers, and the design of the furnace door and ash cleaning door adopts the fully sealed structure in the form of the child and the mother. During the incineration, the furnace is completely isolated from the outside of the furnace, forming negative pressure combustion, which eliminates the possibility of secondary pollution, especially the treatment of infectious dangerous medical waste, which can highlight its unique advantages.

Quick Comparison

| Settings | Medical Waste Incinerator 100kg remove | Sharps Containers – PBS Series 2 LT remove | Sharps Containers – PBS Series 7 LT remove | Sharps Containers – PBS Series 1.5 LT remove | Manual Needle Destroyer – 1.2 Ltr. remove | STERIPLUS 80 remove | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Medical Waste Incinerator 100kg remove | Sharps Containers – PBS Series 2 LT remove | Sharps Containers – PBS Series 7 LT remove | Sharps Containers – PBS Series 1.5 LT remove | Manual Needle Destroyer – 1.2 Ltr. remove | STERIPLUS 80 remove | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Image |  |  |  |  |  |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SKU | SF1033560130107-2 | SF103356013097-3 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Rating | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Price |

|

|

|

|

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Stock | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Availability | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Add to cart | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Description | Shipped From Abroad

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| Shipped From Abroad

The PBS Series 2 Ltr Sharps Container offers a safe and efficient solution for disposing of syringes, needles, and lancets. With a puncture-proof body, secure locking lid, and biohazard labeling, it’s designed for medium-volume use in clinics, labs, and mobile units. Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| Shipped From Abroad

The PBS Series 7 Ltr Sharps Container offers a large-capacity solution for safe disposal of needles, syringes, and sharp medical waste. With a puncture-proof body, dual-locking lid, and biohazard labeling, it's ideal for hospitals, labs, and high-traffic medical facilities.

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| Shipped From Abroad

The PBS Series 1.5 Ltr Sharps Container provides a reliable and spacious solution for disposing of used needles, syringes, and lancets. Designed for clinical and mobile use, it features a secure locking lid, a puncture-resistant body, and compliance with biomedical waste safety standards.

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| Shipped From Abroad

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| Shipped From Abroad

INTEGRATED INFECTIOUS WASTE PRE-SHREDDING AND STEAM STERILIZATION SYSTEM

Tesalys STERIPLUS ™ systems are the ideal solution to safely inactivate your infectious waste on site. Their integrated TESASHRED ™ shredding system not only allows a consequent reduction in the volume and weight of waste, but also guarantees their treatment at heart.

Click here to download CatalogueDelivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Content | CharacteristicsThe main characteristics and scope of application of incinerator LDF series medical waste incinerator is a medical waste incineration equipment with independent intellectual property rights developed by Shandong Lvdu Environmental Equipment Co., LTD., which introduced the world's advanced medical incinerator technology and organized technical experts to tackle key problems. The equipment has the characteristics of full closure, small size, high incineration efficiency, reasonable process, leading technology, and high degree of harmfulness. It is an ideal garbage disposal equipment for all kinds of hospitals, hotels, stations, large commercial institutions, enterprises, and public institutions. Main features: 1. Gasification incineration technology is applied to the incineration of syringes, drip containers and other medical equipment as well as all kinds of paper waste, bandages, absorbent cotton, all kinds of medical sewage and all kinds of waste discharged by hospitals and medical institutions. 2. Using gasification incineration method, the waste generated every day can be incinerated once. 3. The use of gasification incineration, mixed incineration, burnout treatment and other technologies, so that the exhaust smoke, soot content is lower than the national emission standards. 4. Fully enclosed operation, suitable for the treatment of infectious medical waste, to avoid secondary pollution. 5. Small size, small footprint. 6. The series of incinerators are divided into fuel oil and gas, and users can use different types according to their needs. Technical characteristics of incinerators LDF series medical waste incinerator adopts the most advanced incineration method of primary pyrolysis gasification + wind cocombustion + secondary incineration + burnout treatment. The design of the primary combustion chamber of the incinerator adopts the gasification incineration technology to make the temperature in the incinerator shift from 200ºC to 400ºC, and the waste will not produce frit, slag, sintering and other problems in the incineration process. Compared with direct combustion furnace and other furnaces, the dust production of gasification incinerator is very small, and secondary combustion burners and circumferential air supply devices are installed in the secondary mixed incineration chamber. At high temperatures, the combustible gas in the flue gas can be fully burned, and the gas produced by the gasifier can be fully mixed with the air to burn efficiently, preventing the carbon in the gas flame from escaping and the occurrence of late burning. When the flue gas enters the high temperature burnout chamber, due to the use of tangential entry and tangential entry of combustion-supporting air, the flue gas can be fully burned again in the burnout chamber, and the use of rotating airflow for flue gas dust removal. The residence time of the incinerator flue gas in the furnace is greater than 2 seconds, so that the combustible gas in the flue gas and the combustible matter in the fly ash are completely incinerated. The upper part of the incinerator is equipped with dry tail gas purification equipment to adsorb hydrogen chloride and sulfur oxides produced in the incineration, and the odor and other components in the flue gas are decomposed at high temperature. The flue gas purification system is equipped with calcium hydroxide filter brick for neutralizing reaction with acid gas to achieve the purpose of adsorption of acid gas and purification of tail gas. The harmful components in the flue gas are reduced to the national "Hazardous Waste incineration Pollution Control Standard (GB18484-2001)" and other standards below the specified value. The operation control of the incinerator adopts automatic program control, which reduces the labor degree of the workers, and the design of the furnace door and ash cleaning door adopts the fully sealed structure in the form of the child and the mother. During the incineration, the furnace is completely isolated from the outside of the furnace, forming negative pressure combustion, which eliminates the possibility of secondary pollution, especially the treatment of infectious dangerous medical waste, which can highlight its unique advantages. | Features:

Specifications:

| Features:

Specifications:

| Features:

Applications:

Specifications:

| Features:

Applications:

Specifications:

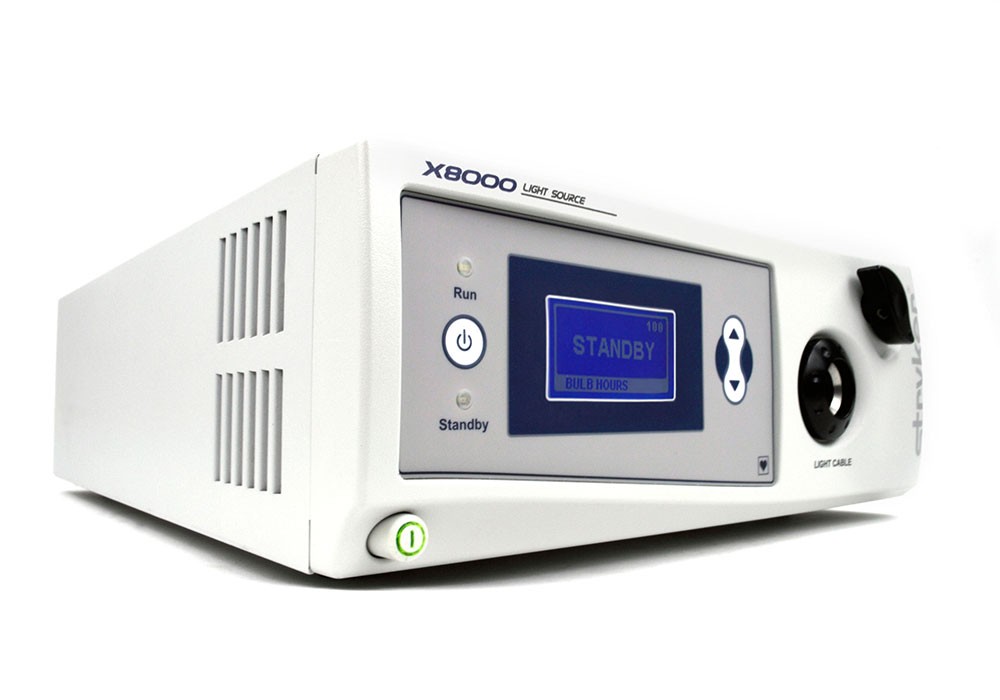

| STERIPLUS 80On-site infectious risk waste treatment solutionhttps://youtu.be/ahPvNNrzIMk?si=8dLL5Pn1YWY_sUM7

FeaturesFully automated

The STERIPLUS™ 80 is an easy-to-use, on-site processing solution.

Large capacity

The loading chamber has a capacity of 80 litres, i.e. 1 TESABOX 80 or 2 TESABOX 40 or 4 TESABOX 20.

Fully integrated system

The STERIPLUS™ 80 is a fully automated solution for pre-grinding and steam sterilization of infectious wastes.

Technical Data

Utilities

Accessories | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Weight | N/A | N/A | N/A | N/A | N/A | N/A | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dimensions | N/A | N/A | N/A | N/A | N/A | N/A | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Additional information |

Reviews

There are no reviews yet.