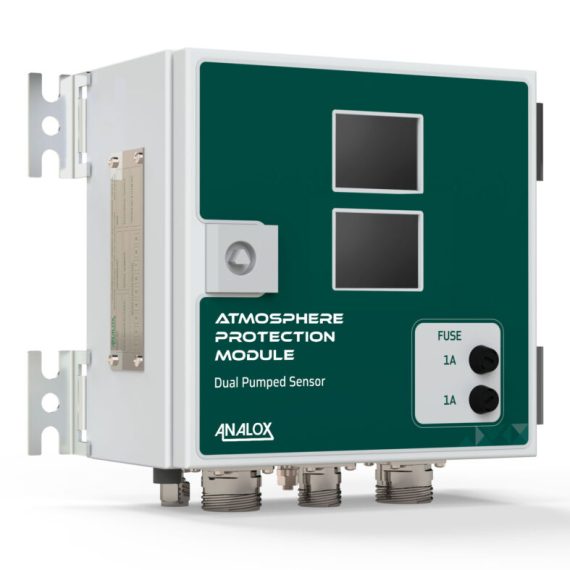

Atmosphere Protection Module

$0.00

Shipped From Abroad

Key Features

- Flexible to meet your specific needs and ensures you meet current legislation

- Measures up to 2 gasses with a choice of; O2 (oxygen), CO2 (carbon dioxide) and R134a (refrigerants). The APM will soon be able to measure VOCs (volatile organic compounds)

- Uses MODBUS RTU communications protocol

- Temperature compensated sensors with PressureSync technology

- Fitted with 2 relays

- Compatible with the Analox Distributed Atmosphere Monitoring solution (DAMS)

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

Description

Descriptions

The Analox APM (Atmosphere Protection Module) is a configurable modular system which has the ability to monitor up to 2 gasses. This unique solution can be used as a stand alone atmosphere monitor or it can be integrated into existing PMS systems.

Technical Specifications

System Specifications

| Operating Temperature | 0°C to +45°C +32°F to +113°F |

| Operating pressure | 700 to 1300mBar |

| Humidity Range | 0 to 95% RH |

| Power | 24vDC (nominal) as standard |

| Communications | MODBUS RTU |

| Relays | 2 as standard |

| Calibration interval | Before mission and / or every 3 months |

Sensor Unit

| Sensor type | Range | Danger | |

| CO2 | NDIR | 0 to 5% / 0 to 30mBar | Toxic |

| O2 (Depleted) | Electrochemical | 0 to 25% / 0 to 2500mBar | Asphyxiation |

| O2 (enriched) | Electrochemical | 0 to 25% / 0 to 2500mBar | Fire/explosion |

| R134a | NDIR | 0 to 1000ppm | Asphyxiation |

| VOCs | PID | 0 to 20ppm | Toxic |

Click here to download Data Sheet

Download Pumped Detectors Technical Manual

Quick Comparison

| Atmosphere Protection Module remove | Conical Glass Flask 250ml remove | Ax60+ Kiosk remove | VENUS SOLO OEM SENSOR remove | Bunsen Burner remove | CARBON MONOXIDE ATMOSPHERE MONITORING SYSTEM remove | ||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Atmosphere Protection Module remove | Conical Glass Flask 250ml remove | Ax60+ Kiosk remove | VENUS SOLO OEM SENSOR remove | Bunsen Burner remove | CARBON MONOXIDE ATMOSPHERE MONITORING SYSTEM remove | |||||||||||||||||||||||||||||||||||||

| Image |  |  |  |  |  |  | |||||||||||||||||||||||||||||||||||||

| SKU | SF1033560130141-16 | SF1033560084-158 | SF1033560130141-6 | SF1033560130141-15 | SF1033560084-155 | SF1033560130141-2 | |||||||||||||||||||||||||||||||||||||

| Rating | |||||||||||||||||||||||||||||||||||||||||||

| Price |

| $5.70 |

|

| $4.25 |

| |||||||||||||||||||||||||||||||||||||

| Stock | |||||||||||||||||||||||||||||||||||||||||||

| Availability | |||||||||||||||||||||||||||||||||||||||||||

| Add to cart | |||||||||||||||||||||||||||||||||||||||||||

| Description | Shipped From Abroad

Key Features

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| In stock

| Shipped From Abroad

Key Features

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| Shipped From Abroad

Key Features

Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| In stock

| Shipped From Abroad

The COSAMS unit was designed specifically for use on submarines, most directly those that operate on diesel engines. Built to exacting military standards for performance, reliability and endurance, the Analox COSAMS uses proprietary Gas Filter Correlation (GFC) technology to specifically analyze the unique properties of CO. The COSAMS (Carbon Monoxide Submarine Atmosphere Monitoring System) has been designed for use on submerged submarines to support life, where crew can be living and working for up to 90 days. Carbon monoxide can be generated on a submarine in several ways, from cooking and fire, to the incomplete combustion of diesel fuel and chlorate candles.Delivery & Availability:

Typically 10-21 working days – excluding furniture and heavy/bulky equipment. Please contact us for further information.

| |||||||||||||||||||||||||||||||||||||

| Content | DescriptionsThe Analox APM (Atmosphere Protection Module) is a configurable modular system which has the ability to monitor up to 2 gasses. This unique solution can be used as a stand alone atmosphere monitor or it can be integrated into existing PMS systems.Technical SpecificationsSystem Specifications

Click here to download Data SheetDownload Pumped Detectors Technical Manual |

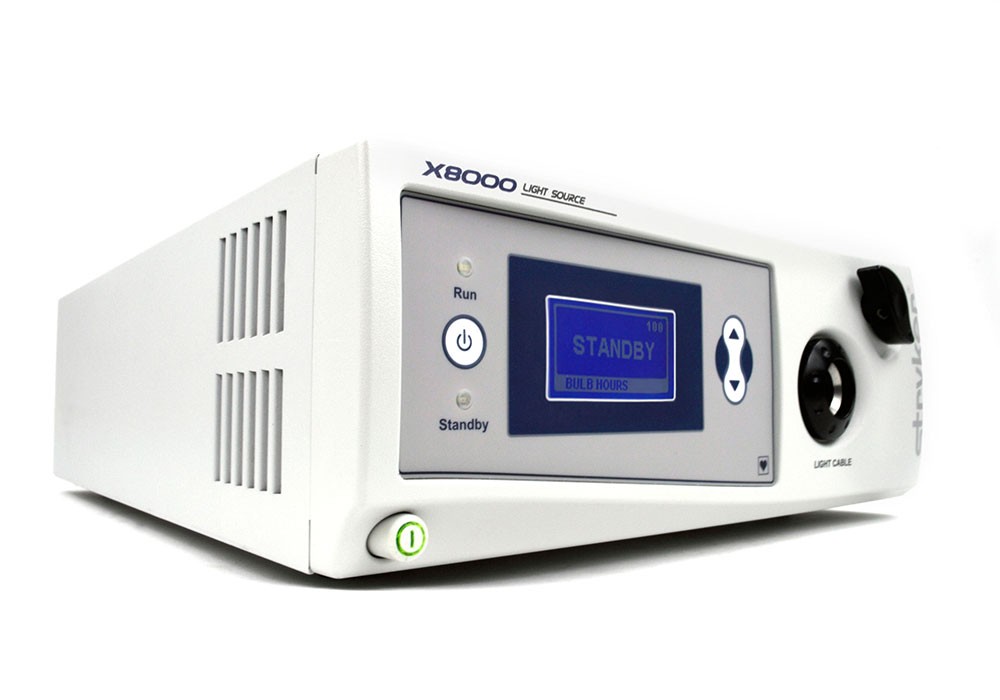

| CO2 MONITOR & ALARM DESIGNED FOR KIOSKS

The Ax60+ Kiosk is a CO2 monitor and alarm specifically designed by Analox to alert personnel to a build up/leak of CO2 using a state-of-the-art infrared sensor. The alarm provides both audio and visual alerts in the case of increased levels of carbon dioxide (CO2). Up to four alarms can be added as needed and the unit does not need periodic calibration. CO2 monitoring with the AX60+ KioskThe Ax60+ Kiosk is a smaller version of the popular Ax60+ carbon dioxide (CO2) monitor. It is simple to wall mount in the area where carbon dioxide (CO2) is stored or piped. The Ax60+ Kiosk sensor needs to be installed at a height of 12-18 inches (305-457mm) above the floor – this is because the carbon dioxide (CO2) that leaks from a gas cylinder is denser than ambient air and can collect at low levels. The alarm should be located above the sensor at about head height or at the entrance to the kiosk.Technical SpecificationSensor Unit | DescriptionThe Venus Solo OEM sensor is a self-contained unit designed for integration into other manufacturers’ equipment and provides a measurement of gas concentration according to specific user requirements. These GFC (Gas Filter Correlation) sensors generate a signal proportional to the infrared absorption of the measured gas. Providing the gas concentration lies within the designed range of the sensor, the signal is periodically compared with a reference gas. Gas concentrations are indicated through the non-linearised analogue signal output. Gas connections to and from the sensor are via suitable fittings on the gas measuring cell. The Venus Solo OEM Series sensors electrical supply is designed to accept 24V DC (3amp max). Our Venus Solo OEM sensor uses GFC (Gas Filter Correlation) technology to give highly accurate gas measurements. The Venus Solo can be integrated into your own gas analyzer or management system and offers the user a 0-2.5v analogue output.The sensor is currently available as either: Carbon dioxide (CO2), carbon monoxide (CO), nitrous oxide (N20), methane (CH4) or nitric oxide (NO). If your application requires a different gas, just let us know and we can customise it to your needs. The Venus Solo is used in Military applications to protect submariners from carbon monoxide (CO) exposure. Technical SpecificationVenus Solo |

| Key Features

Technical SpecificationsClick here to download Data SheetClick here to download Manual | |||||||||||||||||||||||||||||||||||||

| Weight | N/A | N/A | N/A | N/A | N/A | N/A | |||||||||||||||||||||||||||||||||||||

| Dimensions | N/A | N/A | N/A | N/A | N/A | N/A | |||||||||||||||||||||||||||||||||||||

| Additional information |

Reviews

There are no reviews yet.